Buggy

The Vehicle

The devil is in the detail

It was in early 2021 that Neil Bainbridge started thinking seriously about entering a desert rally. His first move was to look for a suitable vehicle upon which to create his vision of the ideal machine for the job, and eventually he bought a classic 1972-model Land-Rover 110.

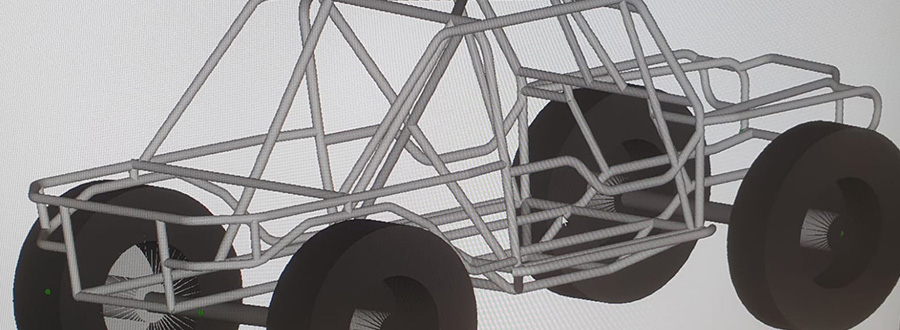

The heart of any desert racer is its chassis and associated suspension systems, and for this Neil sought the advice and later the practical expertise of Matt Dillon at Warwickshire-based WKD Motorsport. Long involved in off-road racing – and subsequently chosen by Neil to be his co-driver for the event – Matt designed and built not only a new tubular frame for the car, but also the internal and external panel work, and then the front and rear axle casings, the latter intended to accept the heavy-duty Nissan differentials that have widely proven themselves ideal for this kind of application.

"It was in pretty poor condition, but for our purposes that didn’t matter at all. I knew I would be discarding any component that might compromise reliability in the harsh conditions we’ll be encountering, so all I really needed were the bare bones."

Neil Bainbridge

It was Matt, too, with both input from Neil and a little bit of good, old-fashioned trial and error, who came up with the height-adjustable full coil-over suspension for each corner of the vehicle. ‘It looks rather complicated,’ concedes Neil, ‘but essentially the dampers – eight, all told – are triple by-pass units to control the bump and rebound, given the relatively long suspension travel we will need. There is also the facility to add an anti-roll bar at the rear, but we shall try to avoid that, if possible, to maintain optimum body articulation on the rough stuff.’

The car’s original six-cylinder petrol engine, designed for relatively relaxed low-speed driving, was never going to be powerful enough, so the next task was to find a suitable alternative. Without too much debate, Neil opted for a brand-new, 7.0-litre V8 Chevrolet LS, again a proven and popular unit for all manner of modified road and race cars. ‘It comes all the way from America in a big wooden box, complete with just about every ancillary you need,’ says Neil. ‘Hence the term “crate engine”. You even get the electronic fuel and ignition management system, although that was something we knew we’d be replacing with our own bespoke unit.’

To this power unit would be mated a six-speed automatic transmission from General Motors – also brand-new, of course – and a specially designed three-speed transfer gearbox to provide both rear-wheel drive or all-wheel drive, as required (the former between rally stages), and not least the three overall gear ratios essential for coping with steep gradients on essentially loose and slippery surfaces. ‘Traditionally, serious off-roaders – and any other sort of race car, for that matter – would have manual gearboxes,’ says Neil, ‘but gradually the many advantages of full automatics have become obvious. Besides, with only one arm I can’t drive a conventional manual anyway.

‘There was no easy way of getting rid of the three levers that control the transfer gearbox,’ adds Neil,’ but those are needed only relatively infrequently, and I can reach them with my right hand – that’s one of the reasons why we built the car with left-hand drive. For the same reason there’s a so-called flappy-paddle lever either side of the steering column – both of them providing up- and down-shifts – although we’ve now added two buttons on the floor to do the same job. It’s all about making the car as easy for me – and Matt, of course – to drive as possible.’

All of the peripheral controls and systems – of which there are surprisingly many – have been designed and located with the same aim. ‘It’s a big car,’ admits Neil, ‘but we had to squeeze in a lot of kit, making sure the delicate electronic bits will be protected from sand and heat. There’s a sat-nav system, for instance, with no fewer than five GPS transponders on the roof. That’s partly a safety requirement, so we can be located in the event of a breakdown or accident, but we’ve also incorporated a function to adjust the fuelling and ignition for height above sea level, as determined by our position, rather than an altimeter – we could be crossing some quite high mountain passes. Engine intake temperatures are monitored, again with changes to the fuelling to suit, and we can keep an eye on gearbox and final-drive temperatures.’

One of the driver’s major tasks, whether it be Neil or Matt, is to manage not just the overall fuel consumption, but crucially also its distribution within the chassis. ’Get that wrong, and the car could become dangerously unstable,’ says Neil. ‘And there is a lot of fuel involved. The main tank, in the middle towards the rear, holds 170 litres [nearly 40 gallons], with another 90 litres [20 gallons] in two side tanks. That’s 350 litres [around 80 gallons] all told, although at probably roughly four miles per gallon on sand that’s going to start dropping fairly quickly. We reckon we’ll get through at least 1700 litres [nearly 380 gallons] during the event. And with no refuelling on individual daily stages, which can be as long as 600km [nearly 400 miles], we have to make sure we always have enough to make it back to base camp.’

The project’s other big consideration – and expense – is tyres. Made specifically for use on a mixture of soft sand and hard, flinty stone, and mounted on equally specialised wheels, they measure a massive diameter. ‘We’ll need at least a dozen,’ says Neil, ‘with six on the car – two spares, in other words – at any one time. And unfortunately we won’t be able to repair them. Once they get a puncture they’re finished.’

Servicing, too, will be a significant responsibility. Neil is planning on having a five-man back-up team to set up and break camp each day, and not least to maintain the engine and transmission in peak condition. ‘That will mean the usual oil and filter changes,’ says Neil, ‘and the prop-shafts and final drives are going to need close inspection. The air filter – with a sand spinner on each of the two intakes on the roof, and a three-stage element – is probably going to need cleaning out with a shovel. I’m not expecting the brakes to take too much punishment, as they would on one of our racing 911s, but pads and fluid will need to be changed at least once, and the exposed hard lines and hoses examined after each stage.’

For all of Neil’s commendable boldness, personal comfort and safety have not been neglected. ‘Even in April, the big issue in the desert is going to be heat – and there’s no way we could fit air-conditioning. Both Matt and I have to wear full fire-proof race overalls – and helmets, of course – so the top halves of our suits have built-in water cooling. Paradoxically, though, I have fitted a simple heater. It’s famously cold in the desert overnight, and we night need something to clear the windscreen first thing in the morning – and even warm ourselves up after a few hours in a tent, come to that.’

Other safety features abound throughout the vehicle. The fuel tanks have the obligatory FIA-approved foam filling to prevent explosion when punctured, and there is both a built-in fire-extinguishing system – with dedicated nozzles within the engine compartment – and a separate 2kg hand-held unit for each occupant. There’s an approved first-aid kit, a special cutter for slicing through seat-belts if a buckle jams, three litres of drinking water apiece in a bladder beside each seat, a tow-rope, sand ladders and shovels, distress flares, and even a cigarette lighter. A simple magnetic compass, too, in case all other navigation aids fail. Among the more serious pieces of equipment is a so-called sand anchor.’ The idea is that if the vehicle turns over on a soft surface you bury the anchor, and then use the on-board winch and cable to pull against it to get it upright again.

‘I think that, between us, we and the organisers seem to have thought of just about everything,’ says Neil with one of his characteristic smiles. We won’t know for sure until next April, of course, but we’re planning a serious on- and off-road testing programme to be carried out over the next few months, and I’m confident there will be only a few issues to deal with after that.’